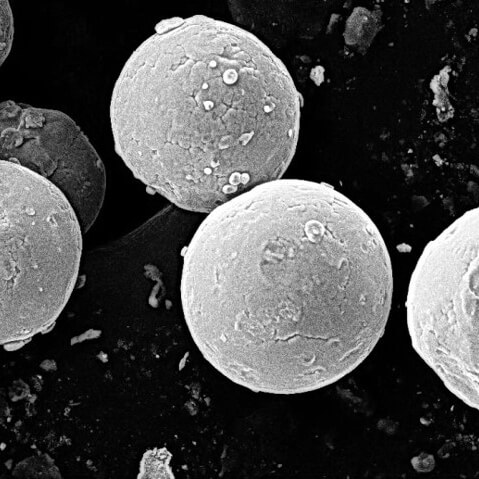

metal powders for additive manufacturing

As part of an overall growth effort focusing on the basic additive manufacturing solutions that drive Industry 4.0, Botlikh Radio Plant, OOO is developing a system for plasma-spraying powdered metals. This project is focused on developing versatile production equipment that would make it possible to spray any available metals fed in the form of wire, and, if necessary, to precondition and wiredraw special alloys to be used in the spraying process.

The tests carried out on a prototype plasma spraying unit have shown good results, including a sphericity of at least 90 %, which is one of the most important performance metrics for modern 3D printers, as well as a good particle size distribution at the output end of the spraying process, yielding 30 % or more of material fit for use in modern 3D printers.